SEARCH

MENU

-

제품

- 애플리케이션 유형 영상 및 카탈로그

-

승객 모니터링 시스템

승객 모니터링 시스템

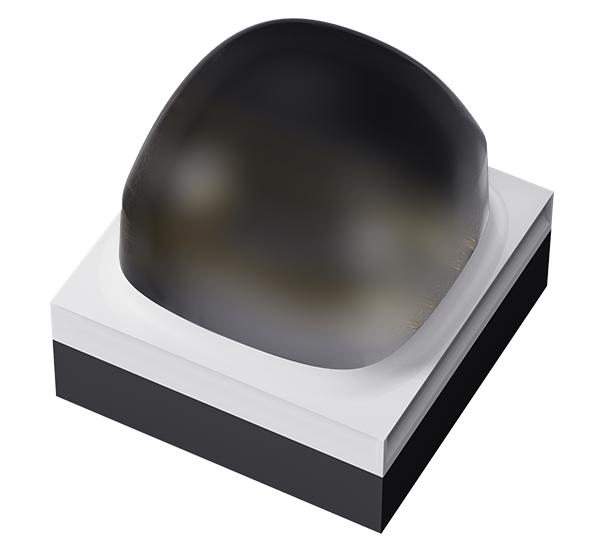

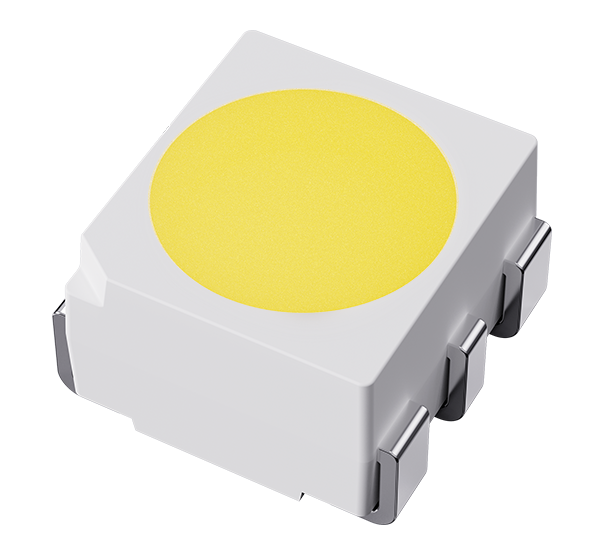

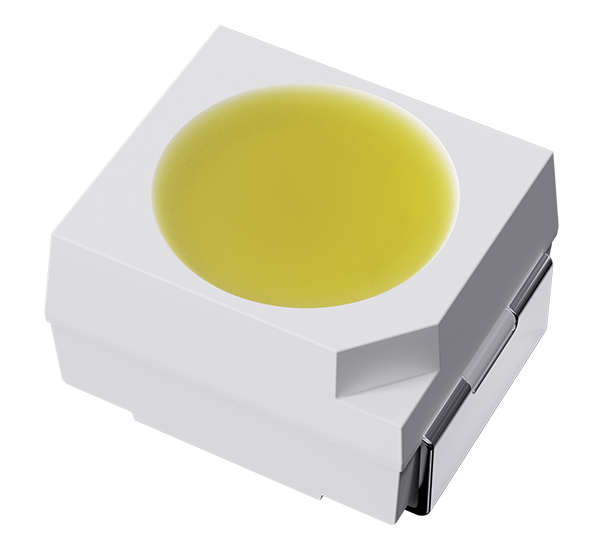

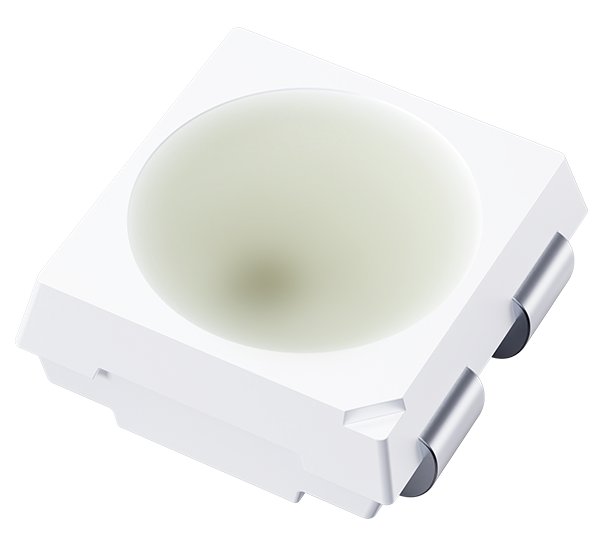

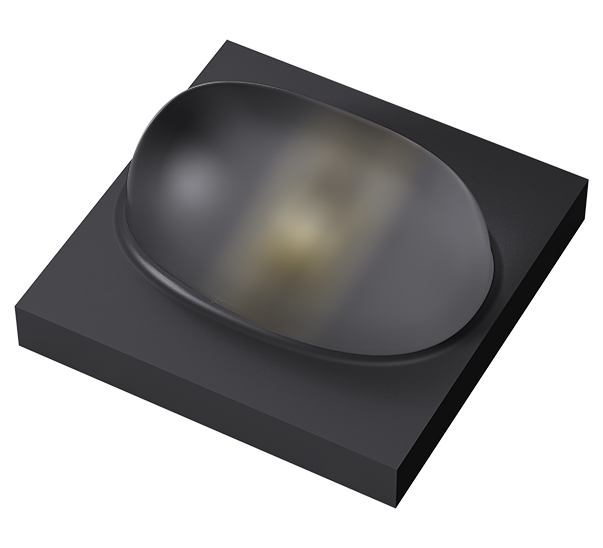

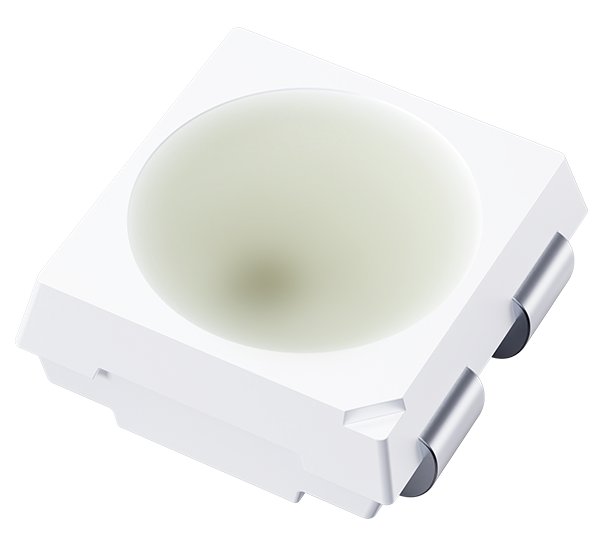

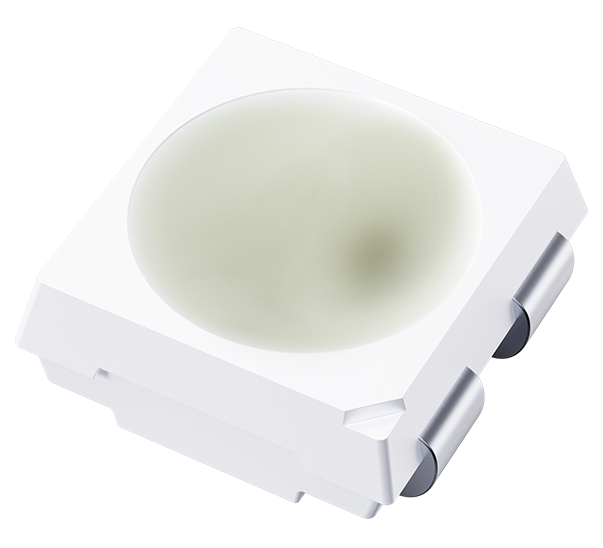

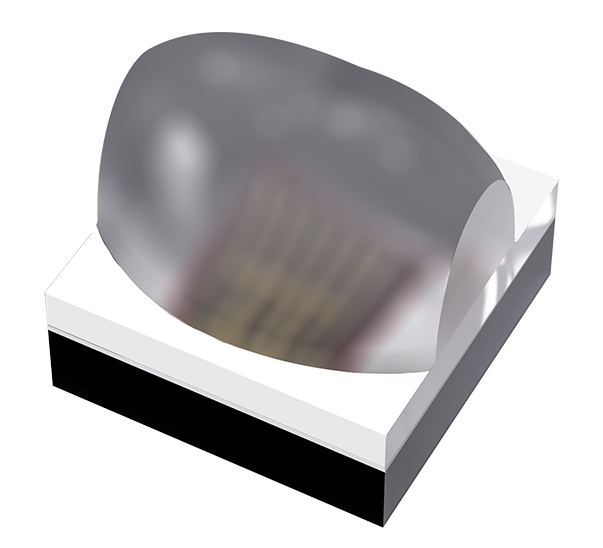

Power Dome LED 3838 130°/150°

An AEC Q102 Qualified solution, engineered with low thermal resistance...

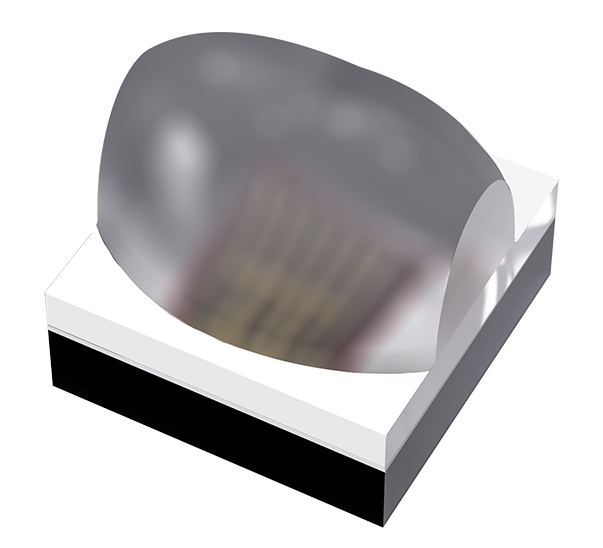

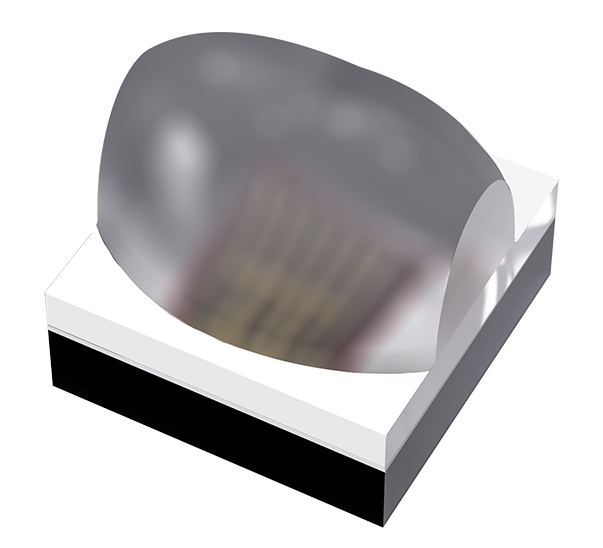

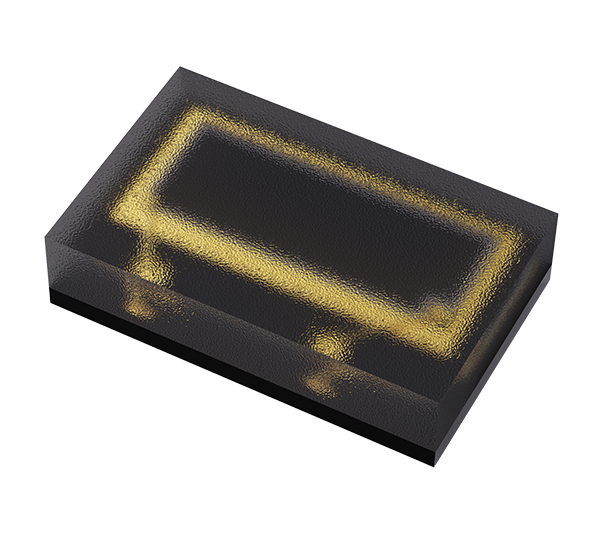

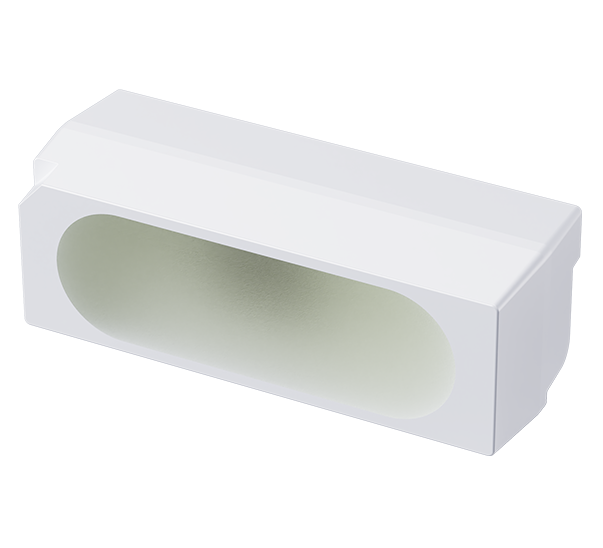

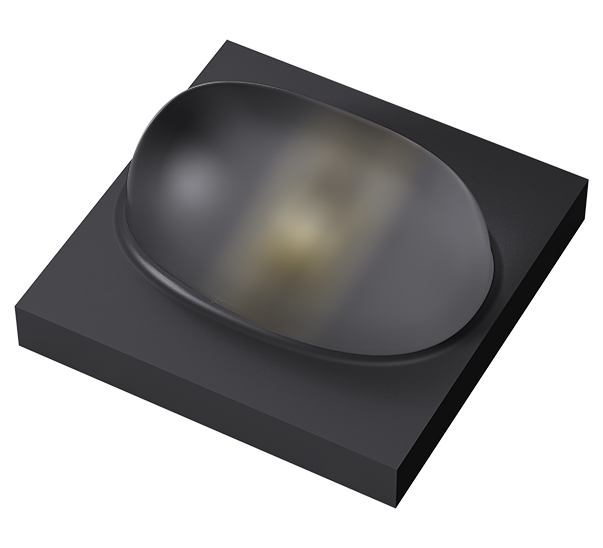

Power Asymmetric LED 3838 150°x90°

Introducing our AEC Q102 qualified solution, featuring low thermal res...

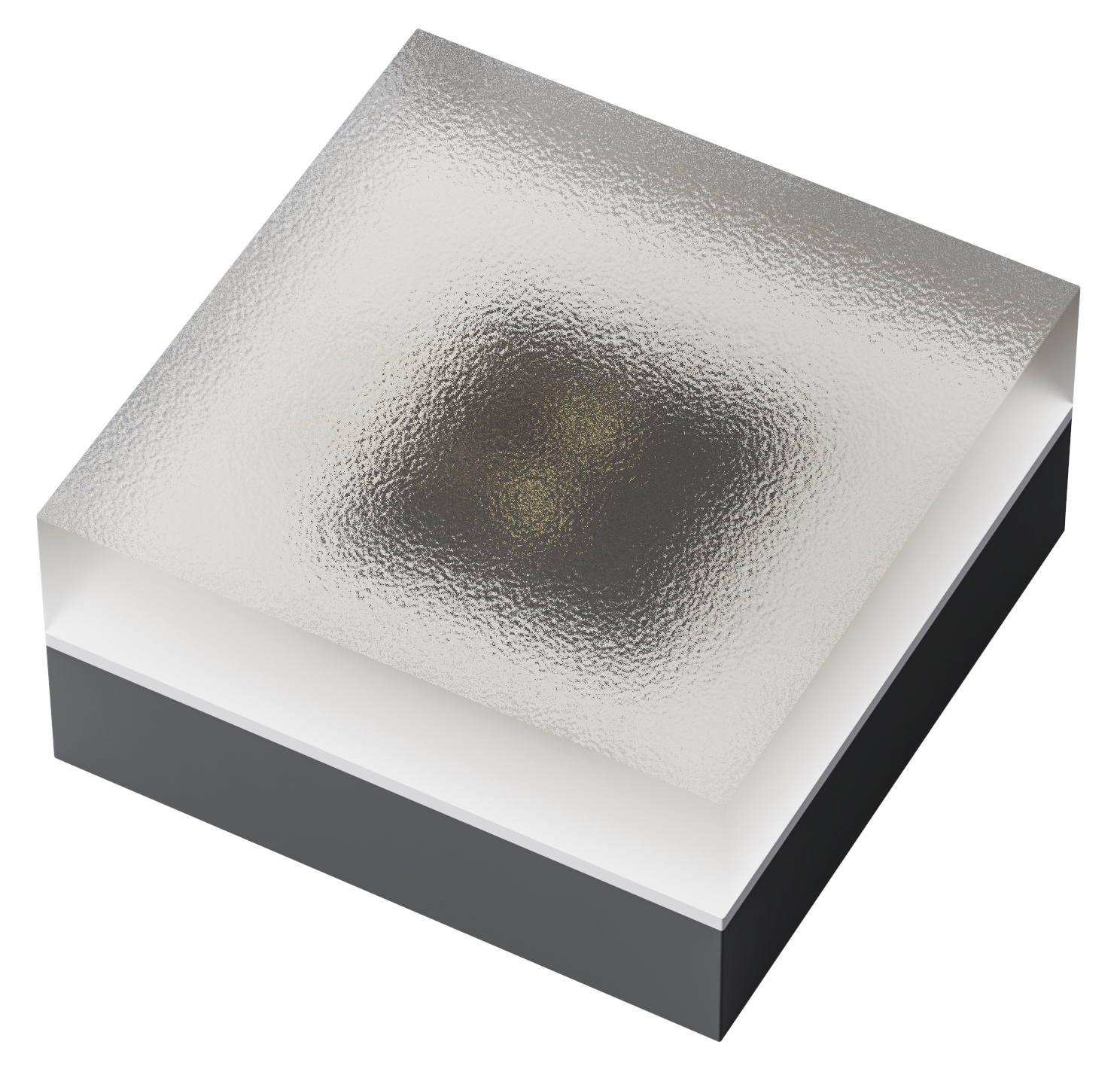

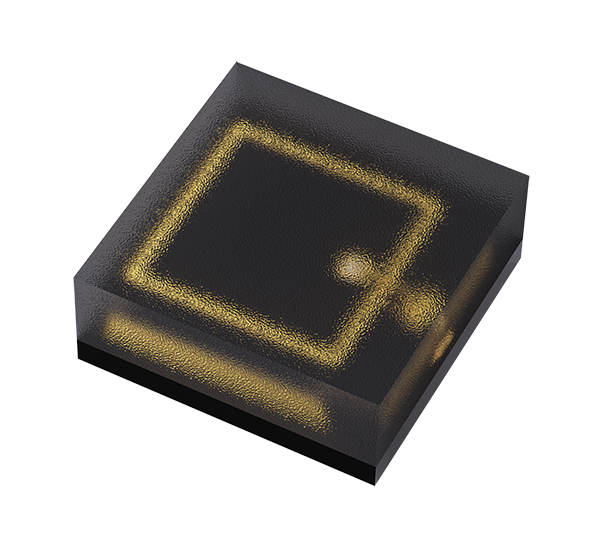

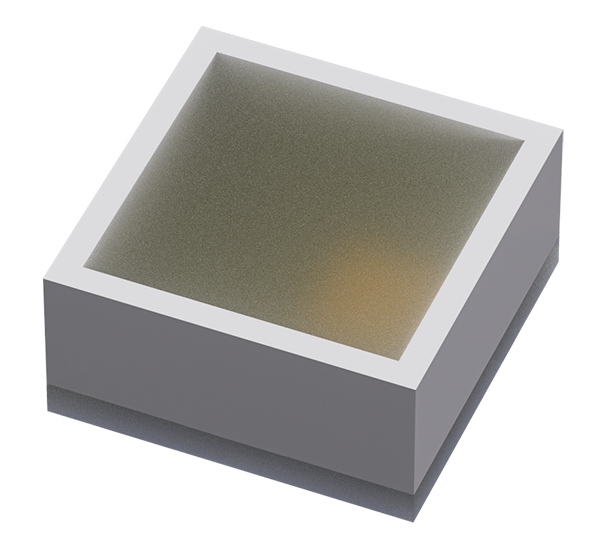

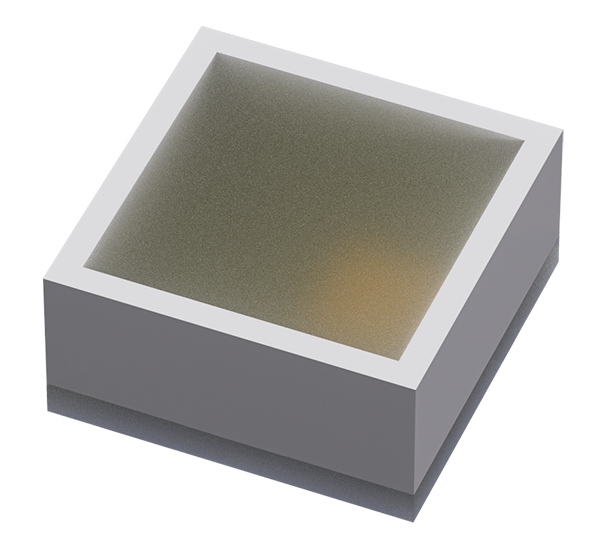

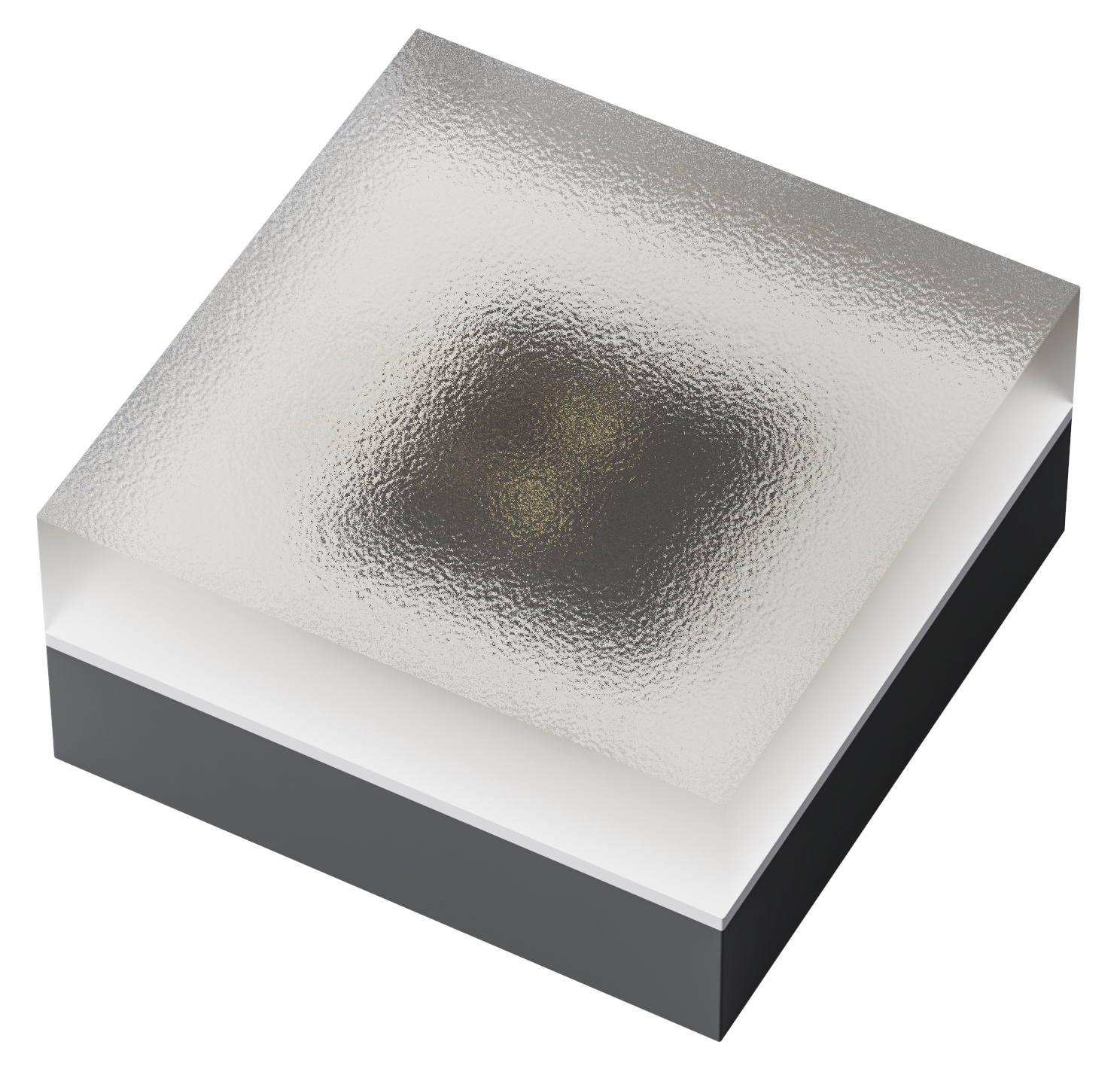

Power Flat LED 1616 120°

An AEC Q102 Qualified solution, boasting low thermal resistance and ...

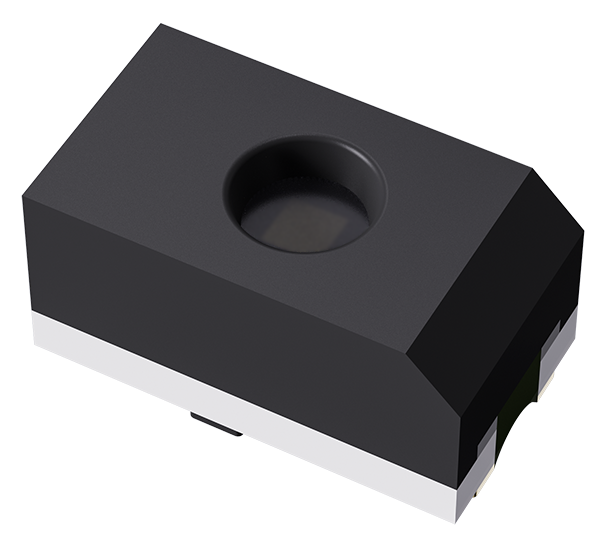

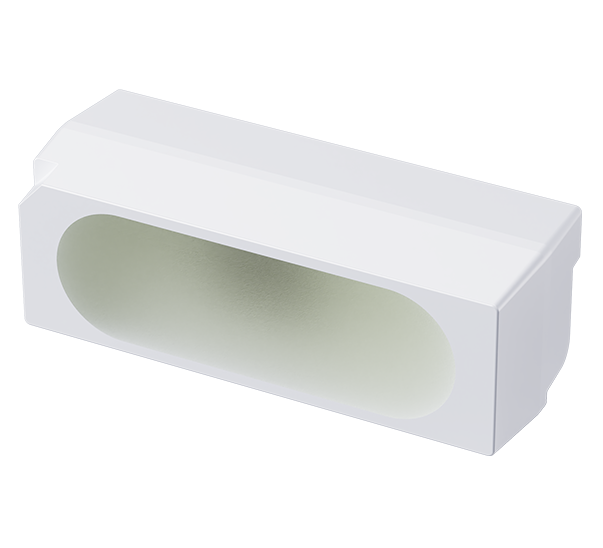

Power Off-Axis LED 3838 135°x35°

The brilliance of off-axis LED lighting - reducing glare, optimizing e...

Power Asymmetric LED 1616 110° x 130°

컴팩트한 정밀함, 최대의 효과

운전자 모니터링 시스템

운전자 모니터링 시스템

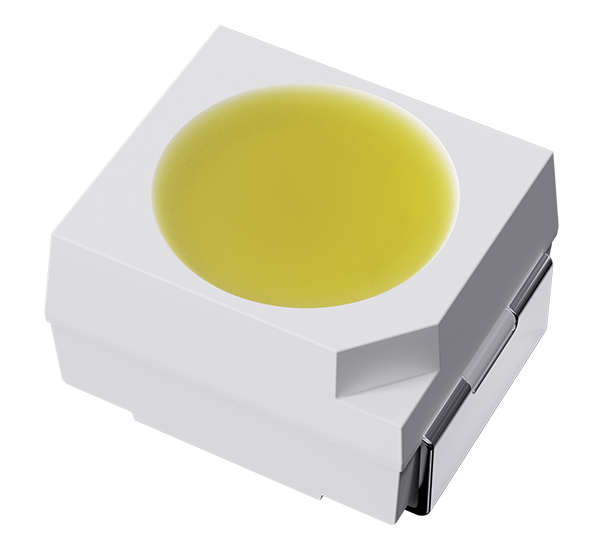

Power Dome LED 1616 80°

AEC Q102 Qualified series, engineered with low thermal resistance and ...

Power Dome LED 3838 40°/50°

Rated Class 3B for corrosion robustness, perfectly suited for Driver ...

Power Dome LED 3838 80°/90°

Perfectly tailored for Driver Monitor Systems and security application...

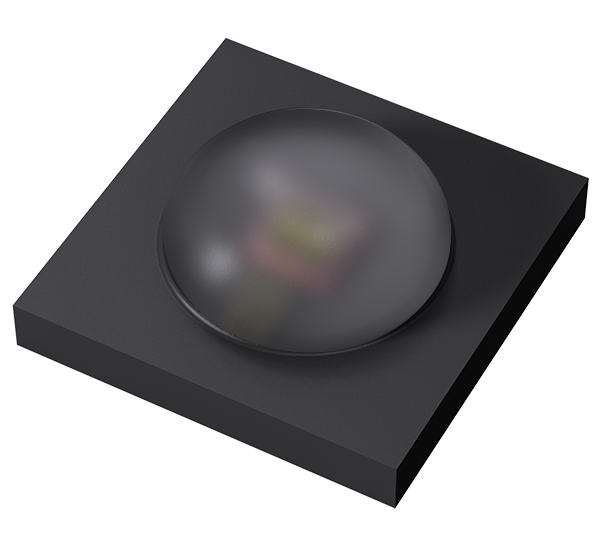

Power Asymmetric LED 3838 45°x25°

An AEC Q102 Qualified solution, featuring low hermal resistance, 2kV E...

Power Off-Axis LED 3838 135°x35°

The brilliance of off-axis LED lighting - reducing glare, optimizing e...

Power Asymmetric LED 1616 110° x 130°

컴팩트한 정밀함, 최대의 효과

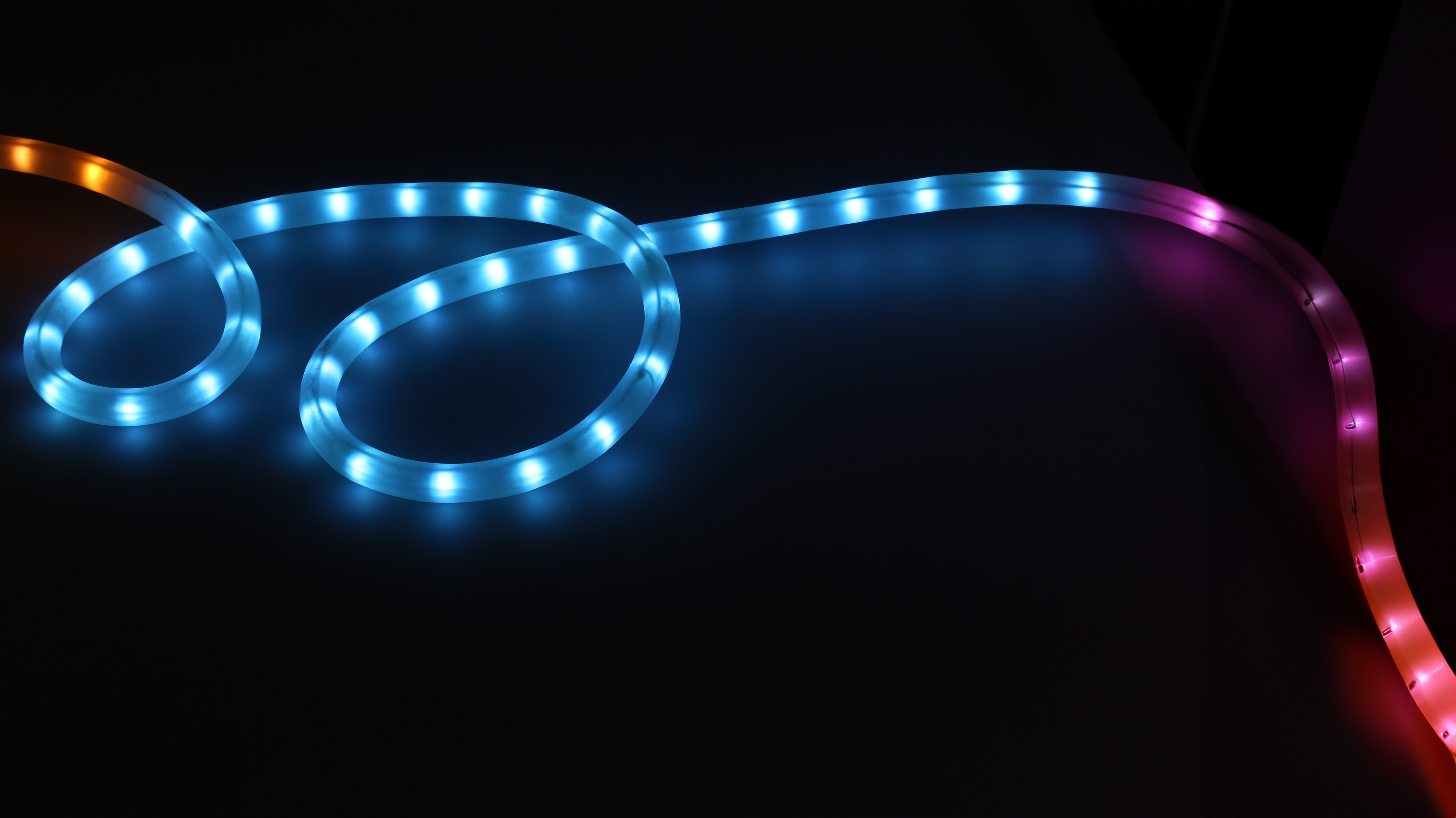

내장 무드램프

TOP LED 3030 RGB

Elevate your ambiance with our mid-power RGB LED, seamlessly coupling ...

TOP LED 3433

PLCC chips in red and amber, offering high color purity for functional...

TOP LED 3528

Conventional PLCC2 product series covering various color selections an...

TOP LED 3433 RGB

0.2W PLCC6 RGB series, ideal for creating a variety of colors in ambie...

ICLED EVO 3838

뛰어난 색상 변화를 정확하게 구현하여 풍부하고 부드러운 분위기의 색상을 표현합니다.

내장 조명

TOP LED 3030 RGB

Elevate your ambiance with our mid-power RGB LED, seamlessly coupling ...

TOP LED 3528

Conventional PLCC2 product series covering various color selections an...

TOP LED 2214

Conventional PLCC2 product series, featuring a range of colors and ada...

TOP LED 1608

Conventional PLCC2 product series, ideal for exterior applications.

ICLED EVO 3838

뛰어난 색상 변화를 정확하게 구현하여 풍부하고 부드러운 분위기의 색상을 표현합니다.

외장 조명

외장 조명

Power TOP LED 1519

Compact package with chip scale optical window for easily introducing ...

TOP LED 1519 Dual

Compact dual color package with chip scale optical window which is ben...

TOP LED 1519

Robust ceramic 0.5-1W LED, Ideal for design of daytime running and tur...

TOP LED 2720

Compact EMC products for rear lighting, offering a balanced selection ...

TOP LED 3433

PLCC chips in red and amber, offering high color purity for functional...

TOP LED 3433 RGB

0.2W PLCC6 RGB series, ideal for creating a variety of colors in ambie...

착용 용품

IRR LED 2008

SMT 조립 준비 완료: 생산에 손쉽게 통합하세요. 독립된 발광체 제어: 다양한 요구에 유연하게 발광체를 관리하세요.

IRRG LED 2020

SMT 조립 준비 완료: 생산에 손쉽게 통합하세요. 독립된 발광체 제어: 다양한 요구에 유연하게 발광체를 관리하세요.

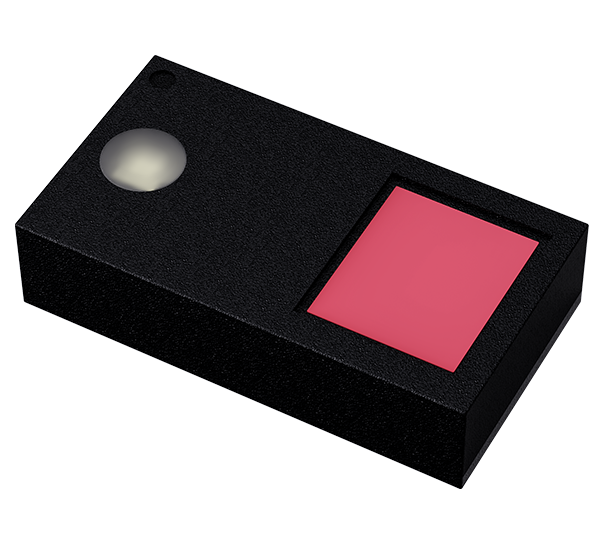

Photodiode 3220

리플로우 솔더링에 적합합니다. 특히 400 nm에서 1100 nm까지의 응용에 적합합니다.

Photodiode 2020

리플로우 솔더링에 적합합니다. 특히 400 nm에서 1100 nm까지의 응용에 적합합니다.

OTS 2020

레이저가 내장된 초소형 광학 트래킹 센서, 사전 보정 완료로 웨어러블 및 협소한 시스템에 최적화됨.

전자 기술

전자 기술

TOP ICLED 3535

Streamlining electrical circuit design for versatile color creation. W...

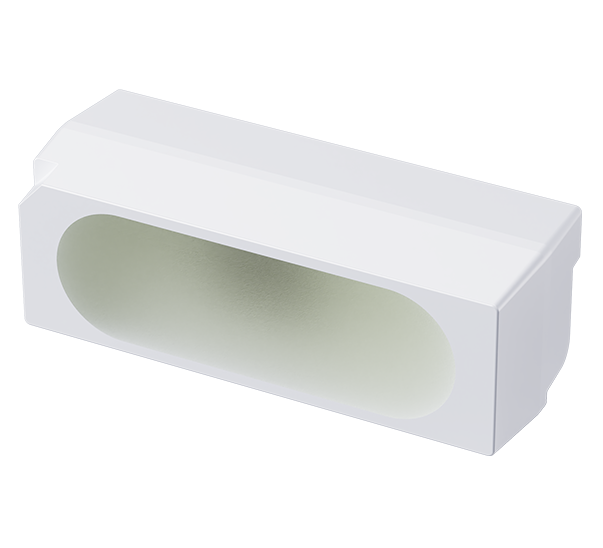

SIDE ICLED 4516

Side-view RGB ICLED, ideal for ambient light applications with an opti...

TOP ICLED 2020

Compact RGB ICLED for consumer, automotive, and display applications.

mini LED 0603

Enhance keyboard indicators with our high-brightness point emitter ser...

Mini ICLED 1212

개인화되고 역동적인 조명 경험으로 일상적인 장치를 변화시키는 소니의 컴팩트한 RGB ICLED 의 매력을 경험해 보세요.

ICLED 5050

Experience brilliance with our high-brightness, large optical window I...

스마트 보안

스마트 보안

Power Dome LED 1616 80°

AEC Q102 Qualified series, engineered with low thermal resistance and ...

Power Dome LED 3838 40°/50°

Rated Class 3B for corrosion robustness, perfectly suited for Driver ...

Power Dome LED 3838 80°/90°

Perfectly tailored for Driver Monitor Systems and security application...

Power Dome LED 3838 130°/150°

An AEC Q102 Qualified solution, engineered with low thermal resistance...

Power Asymmetric LED 3838 45°x25°

An AEC Q102 Qualified solution, featuring low hermal resistance, 2kV E...

Power Asymmetric LED 3838 150°x90°

Introducing our AEC Q102 qualified solution, featuring low thermal res...

-

LEDs

LEDs

SIDE LED 4516 RGB

Side-view RGB ICLED, ideal for ambient light applications with an opti...

TOP LED 3528

Conventional PLCC2 product series covering various color selections an...

TOP LED 1608

Conventional PLCC2 product series, ideal for exterior applications.

TOP LED 3433 RGB

0.2W PLCC6 RGB series, ideal for creating a variety of colors in ambie...

TOP LED 1519

Robust ceramic 0.5-1W LED, Ideal for design of daytime running and tur...

TOP LED 1519 Dual

Compact dual color package with chip scale optical window which is ben...

ICLEDs

ICLEDs

ICLED EVO 3838

뛰어난 색상 변화를 정확하게 구현하여 풍부하고 부드러운 분위기의 색상을 표현합니다.

Mini ICLED 1212

개인화되고 역동적인 조명 경험으로 일상적인 장치를 변화시키는 소니의 컴팩트한 RGB ICLED 의 매력을 경험해 보세요.

TOP ICLED 3535

Streamlining electrical circuit design for versatile color creation. W...

ICLED 5050

Experience brilliance with our high-brightness, large optical window I...

TOP ICLED 2020

Compact RGB ICLED for consumer, automotive, and display applications.

SIDE ICLED 4516

Side-view RGB ICLED, ideal for ambient light applications with an opti...

IR LEDs

IR LEDs

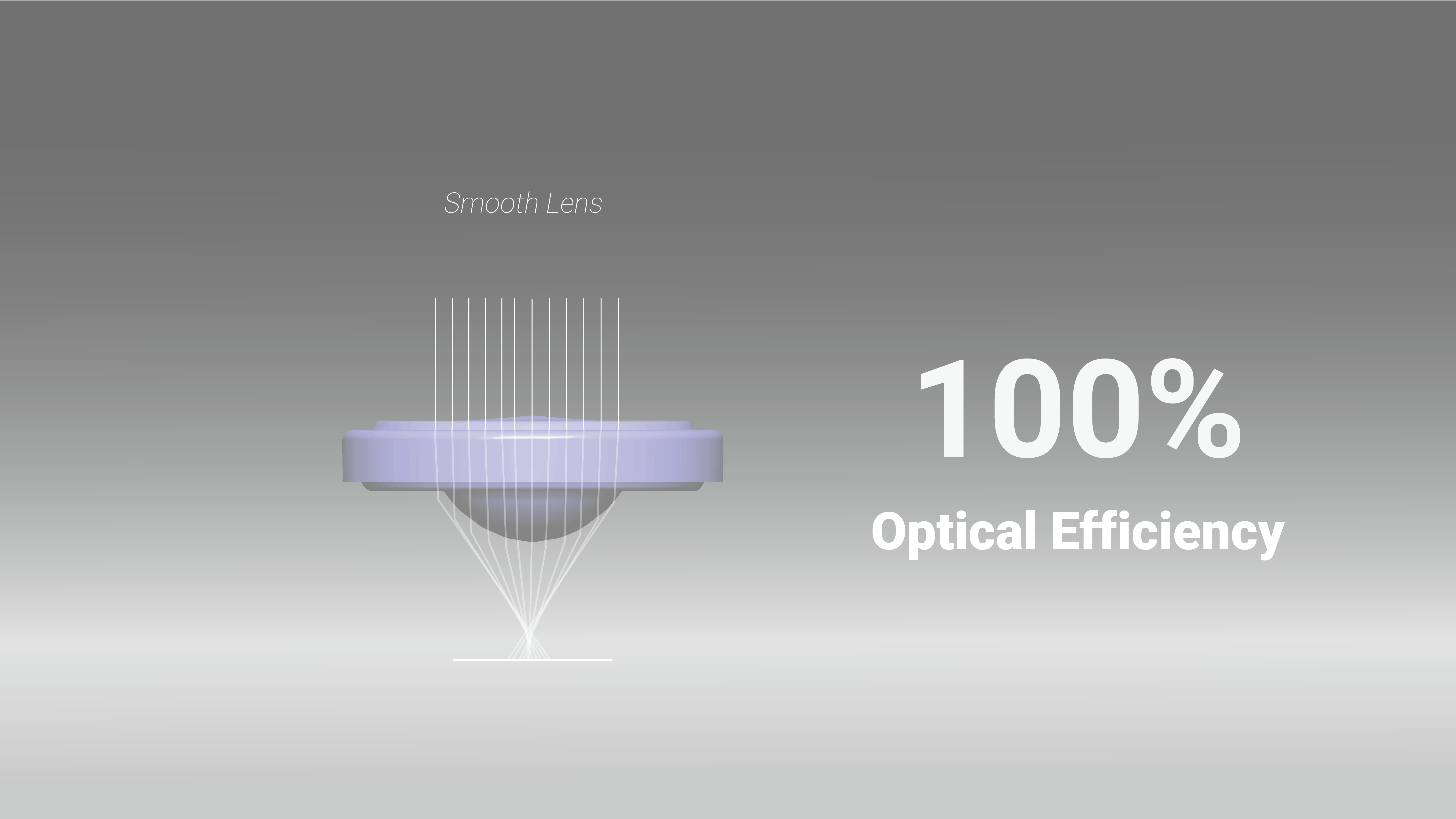

Power Asymmetric LED 1616 110° x 130°

컴팩트한 정밀함, 최대의 효과

Power Off-Axis LED 3838 135°x35°

The brilliance of off-axis LED lighting - reducing glare, optimizing e...

Power Flat LED 1616 120°

An AEC Q102 Qualified solution, boasting low thermal resistance and ...

Power Asymmetric LED 3838 150°x90°

Introducing our AEC Q102 qualified solution, featuring low thermal res...

Power Asymmetric LED 3838 45°x25°

An AEC Q102 Qualified solution, featuring low hermal resistance, 2kV E...

Power Dome LED 3838 130°/150°

An AEC Q102 Qualified solution, engineered with low thermal resistance...

-

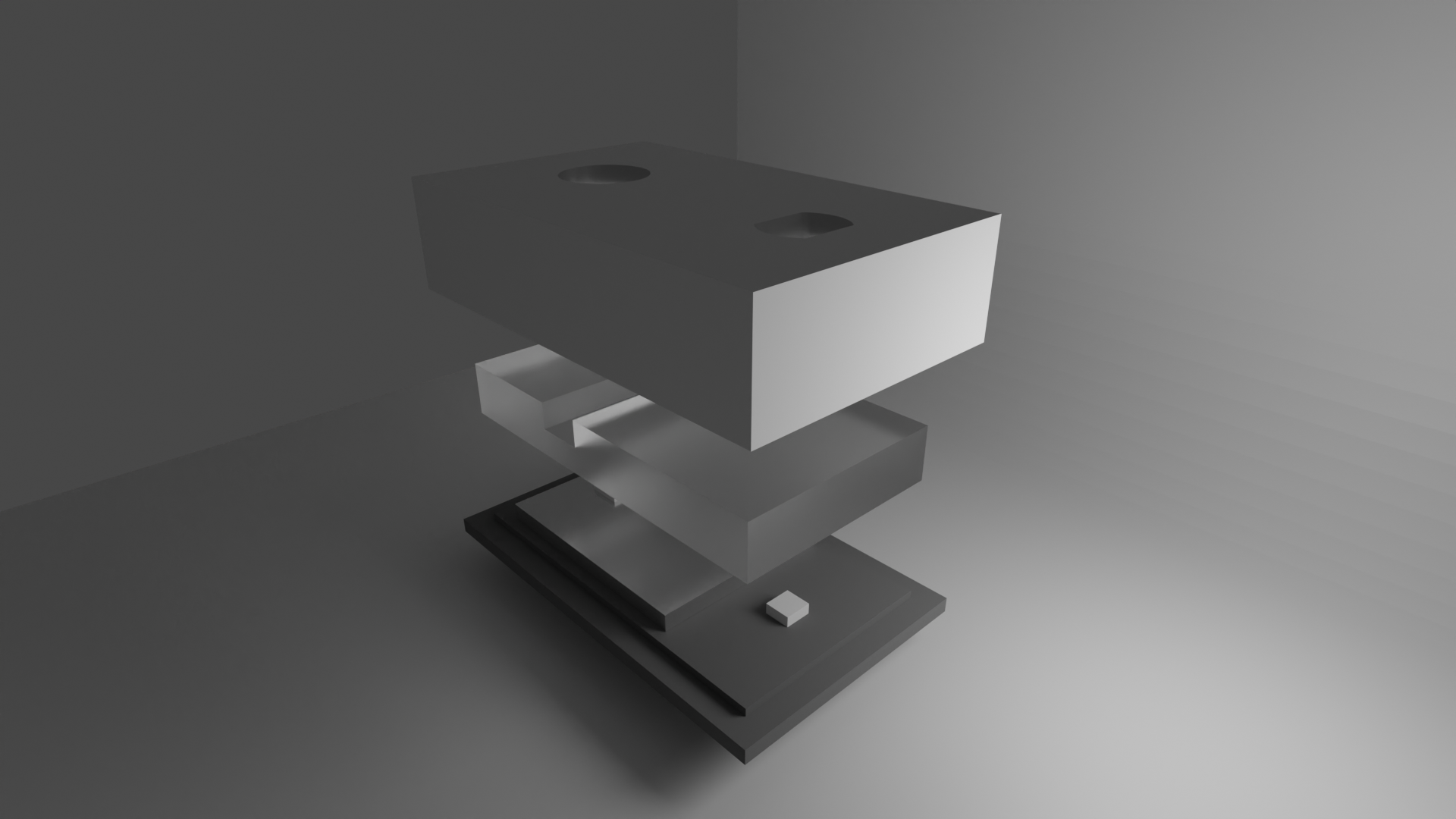

저희의 기술 영상과 제품 카탈로그를 시청하고, 혁신적인 기술을 탐색하며 가장 적합한 제품 정보를 빠르게 확인하세요.

자세히 보기

-

뉴스

- 기술 뉴스 보도 자료 이벤트

-

Mar 06 , 2025

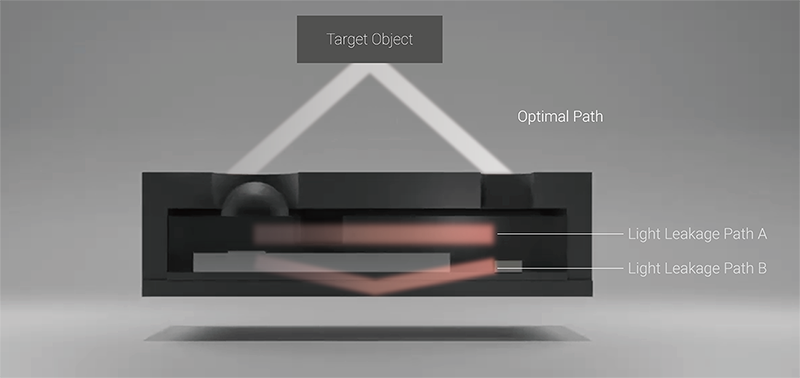

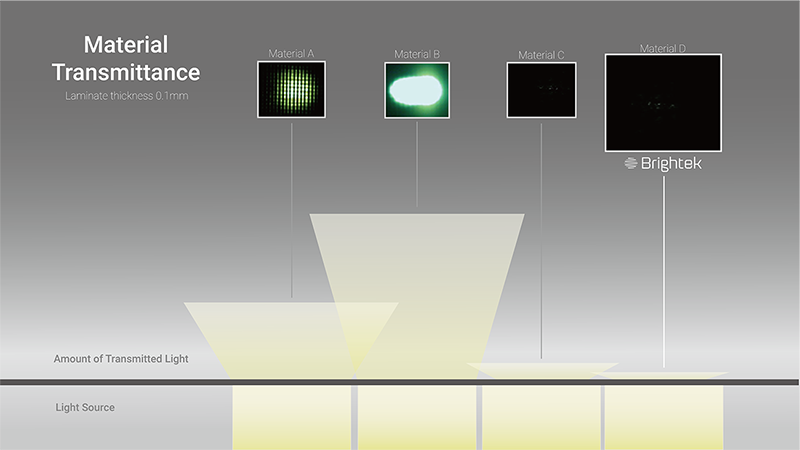

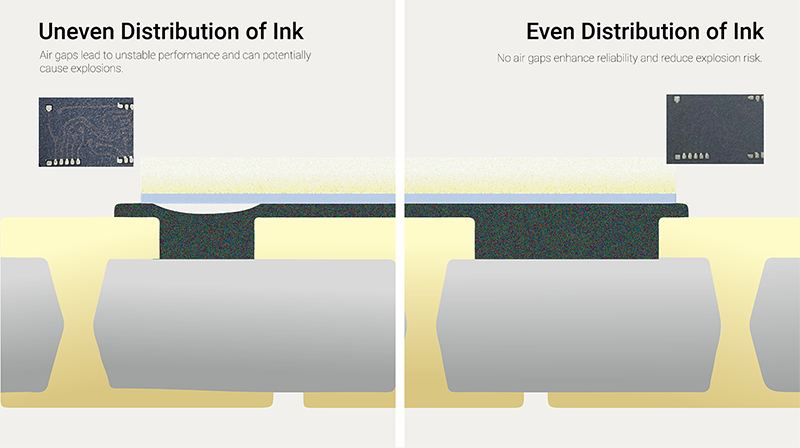

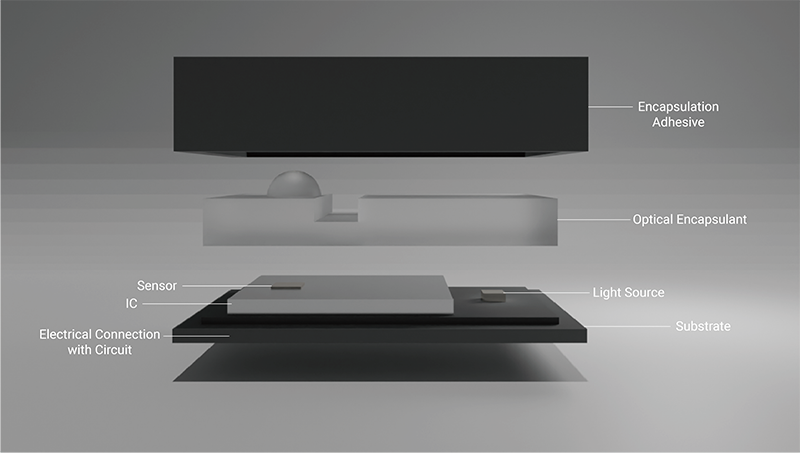

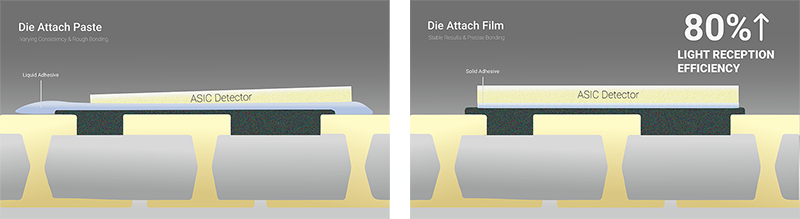

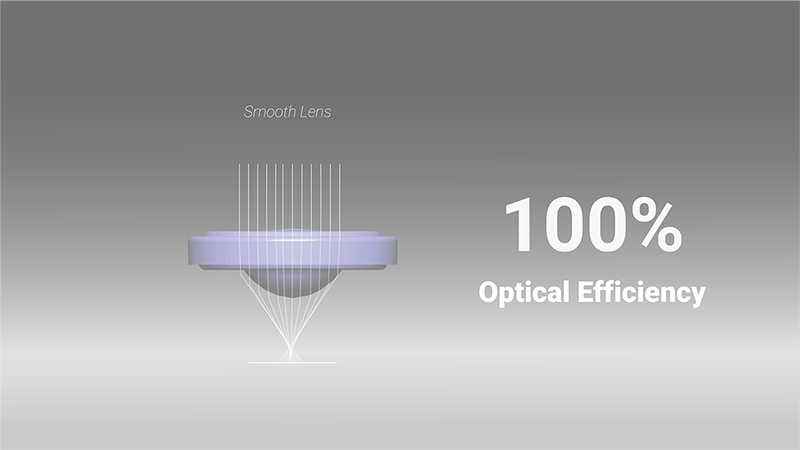

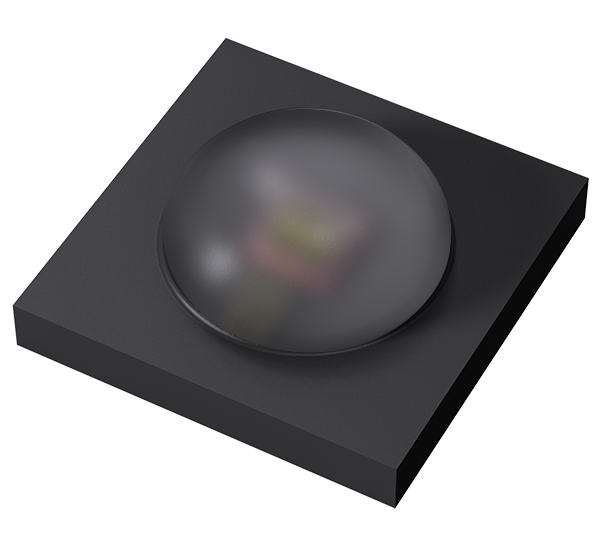

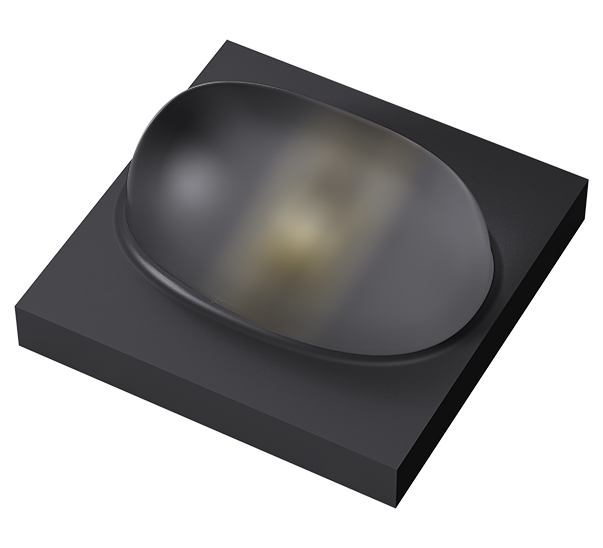

From Design to Manufacturing: Overcoming Sensor Packaging Challenges

Achieving Ultimate Precision: Solving Sensor Packaging ChallengesPrecision in sensor packaging is not just about innovation—it’s about solving real-world challenges for our custome...

자세히 보기 -

최신 뉴스

Jul 01 , 2025

Brightek Optoelectronic Taiwan Headquarters Wins Gold in Office Design at 2025 London Design Awards

Brightek Optoelectronic Co., Ltd. today announced that its headquarters office in Taoyuan, Taiwan, has been awarded Gold Winner in the Interior Design - Office category at the 2025...

자세히 보기

- 지속 가능성

- 회사 소개

- 투자자 관계

Brightek

Brightek