Automotive LED Suppliers with Automotive-Grade Manufacturing Capabilities

SEARCH

MENU

-

Products

- Application Type Videos & Brochures

-

Automotive

Consumer Electronics

Occupancy Monitor System

Occupancy Monitor System

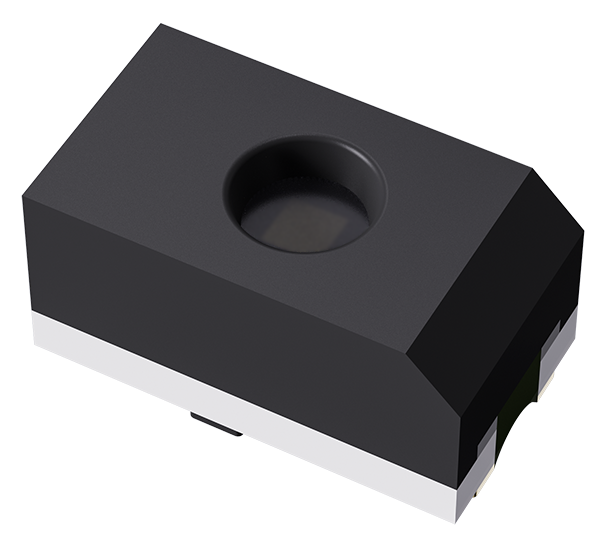

High Power IR LED 3838 (130° / 150°)

This automotive-grade high power IR LED is specifically designed for D...

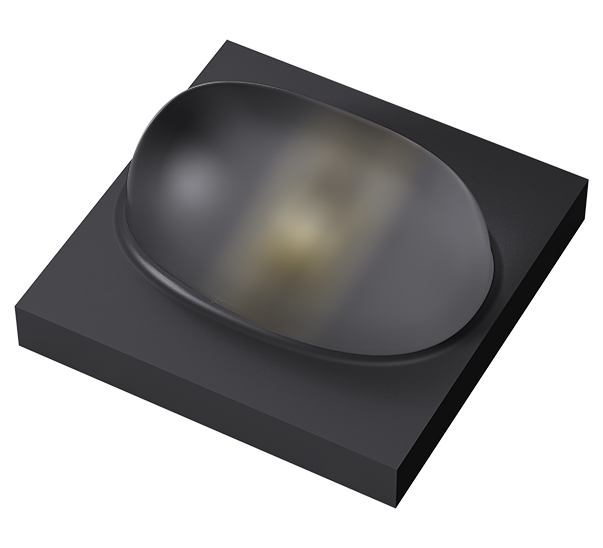

Power Asymmetric LED 3838 150°x90°

The Power Asymmetric LED 3838 150°x90° IR LED features a beam angle of...

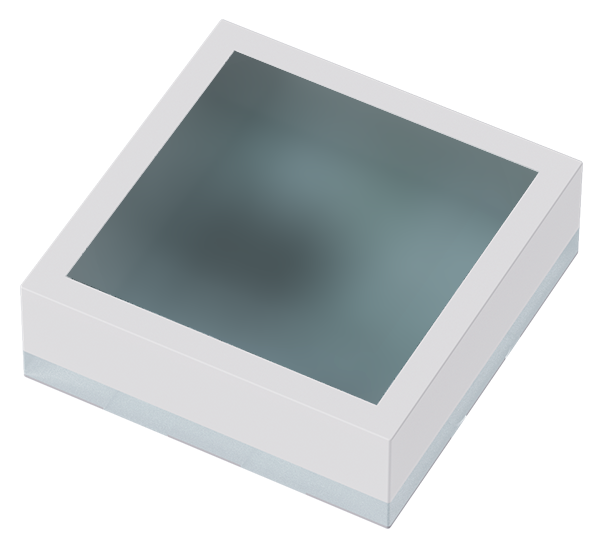

Power Flat LED 1616 130°

The Power Flat LED 1616 130° IR LED features a beam angle of 130° and ...

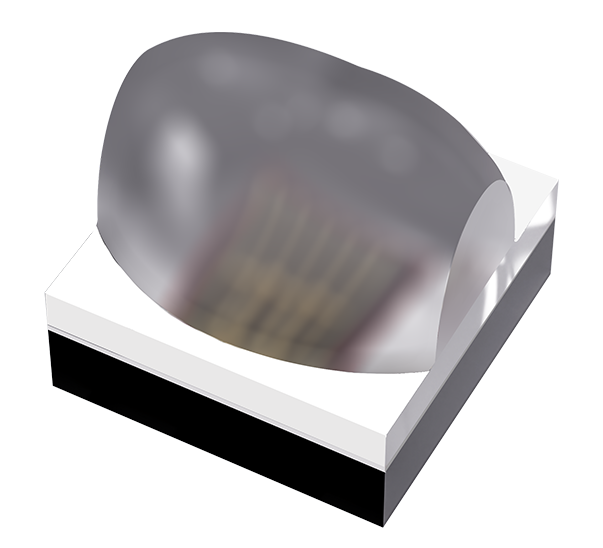

Power Off-Axis LED 3838 135°x35°

The Power Off-Axis LED 3838 135°x35° IR LED features a beam angle of 1...

Power Asymmetric LED 1616 110° x 130°

This miniature automotive IR LED features an asymmetric beam angle of ...

Driver Monitor System

Driver Monitor System

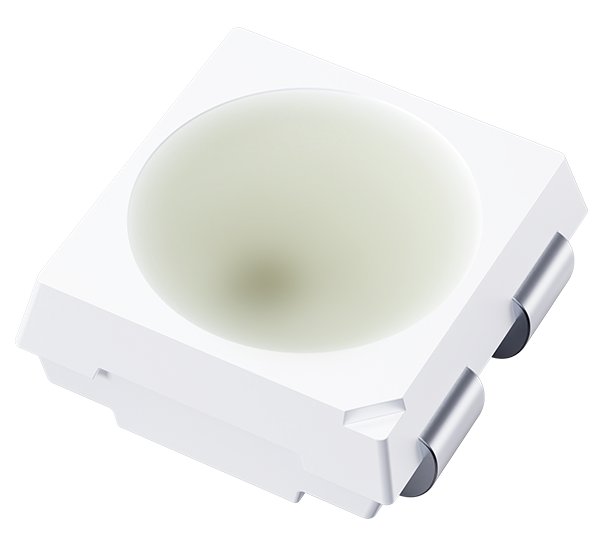

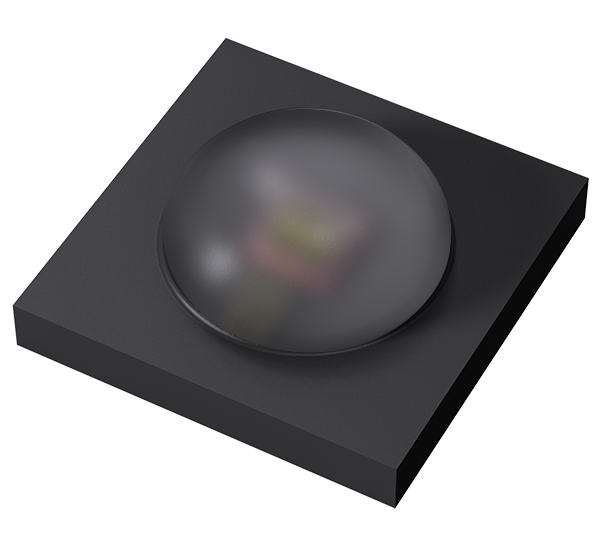

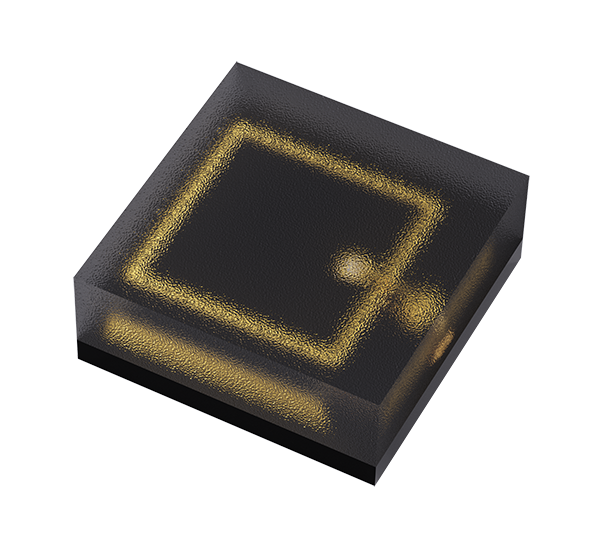

Power Dome LED 1616 80°

AEC Q102 Qualified series, engineered with low thermal resistance and ...

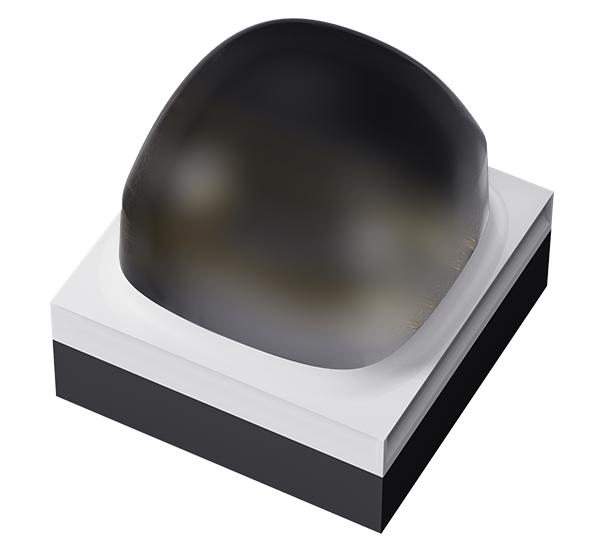

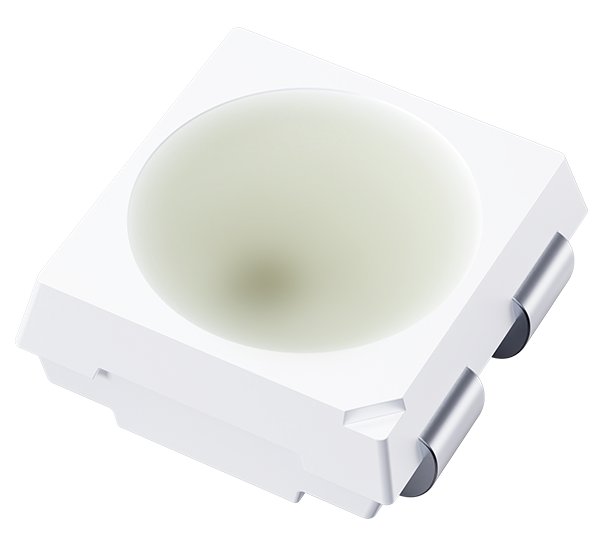

Power Dome LED 3838 40°/50°

Rated Class 3B for corrosion robustness, perfectly suited for Driver ...

Power Dome LED 3838 80°/90°

Perfectly tailored for Driver Monitor Systems and security application...

Power Asymmetric LED 3838 45°x 25°

The Power Asymmetric LED 3838 45°x25° IR LED features a beam angle of ...

Power Off-Axis LED 3838 135°x35°

The Power Off-Axis LED 3838 135°x35° IR LED features a beam angle of 1...

Power Asymmetric LED 1616 110° x 130°

This miniature automotive IR LED features an asymmetric beam angle of ...

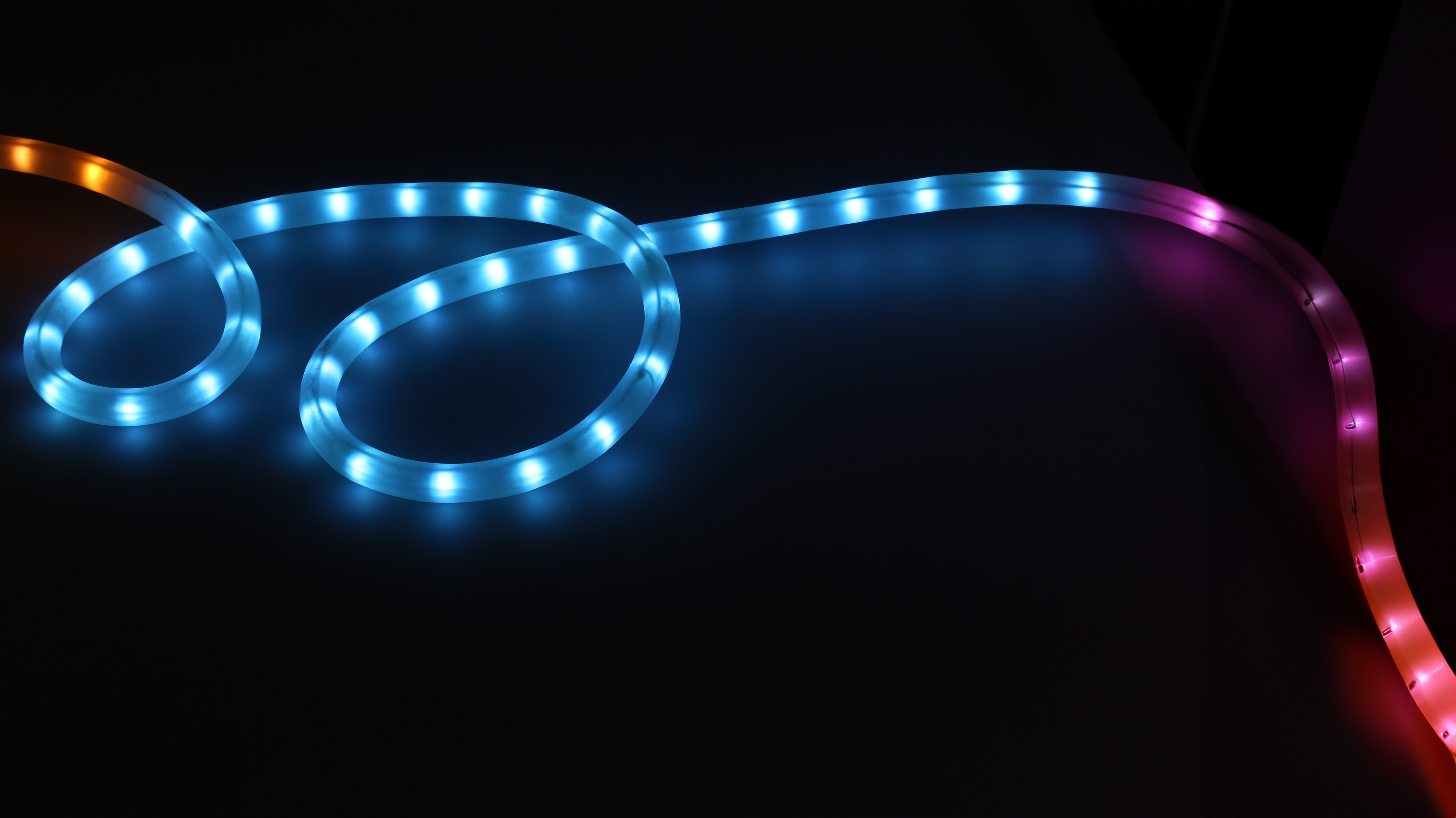

Ambient Lighting

Ambient Lighting

TOP LED 3030 RGB

Elevate your ambiance with our mid-power RGB LED, seamlessly coupling ...

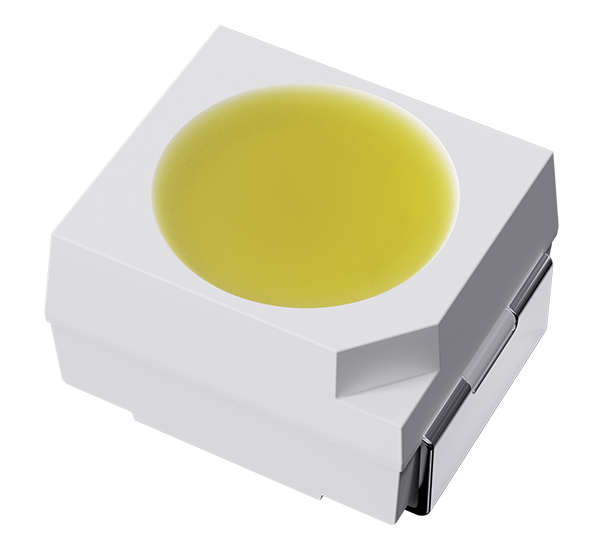

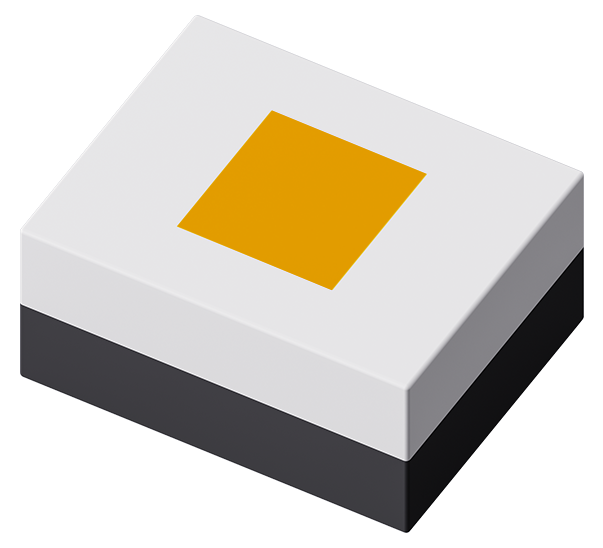

TOP LED 3433

PLCC chips in red and amber, offering high color purity for functional...

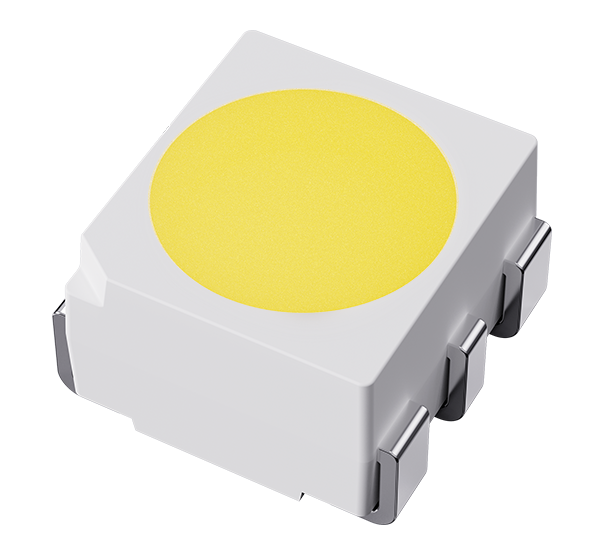

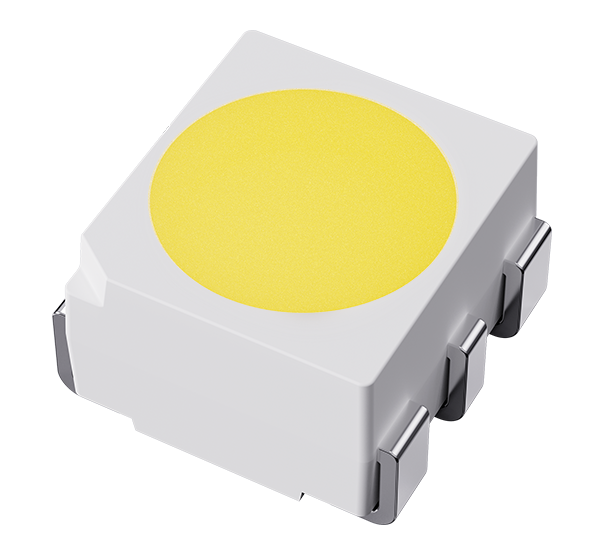

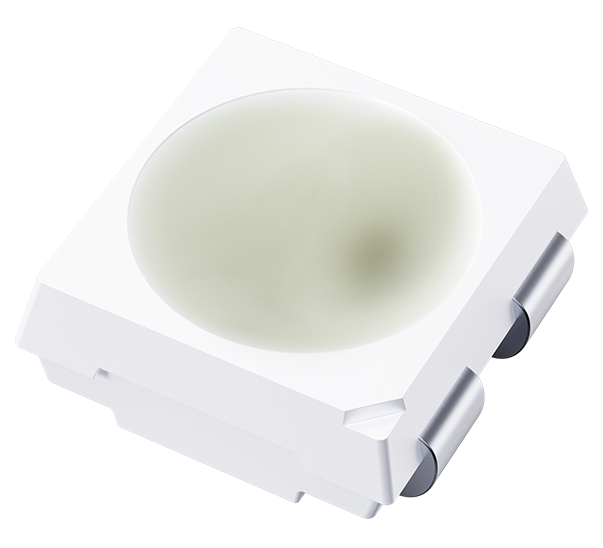

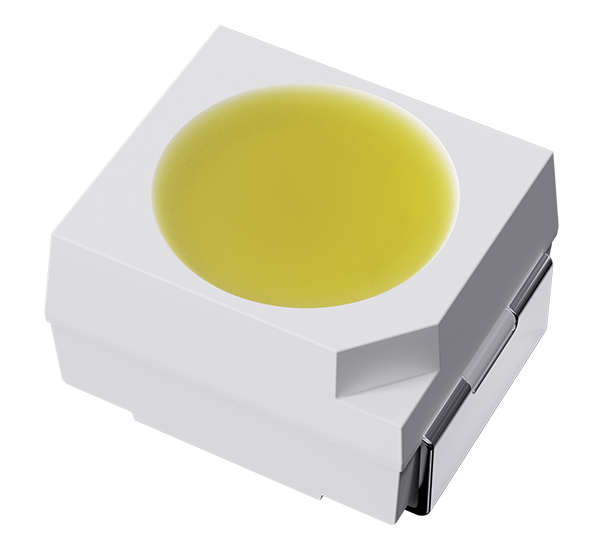

TOP LED 3528

Conventional PLCC2 product series covering various color selections an...

TOP LED 3433 RGB

0.2W PLCC6 RGB series, ideal for creating a variety of colors in ambie...

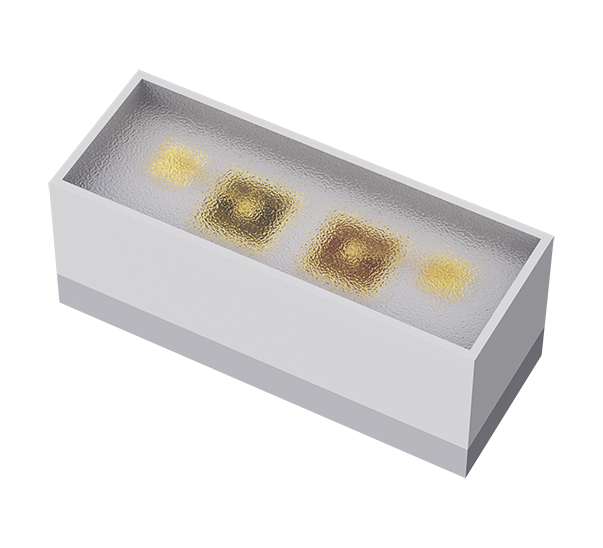

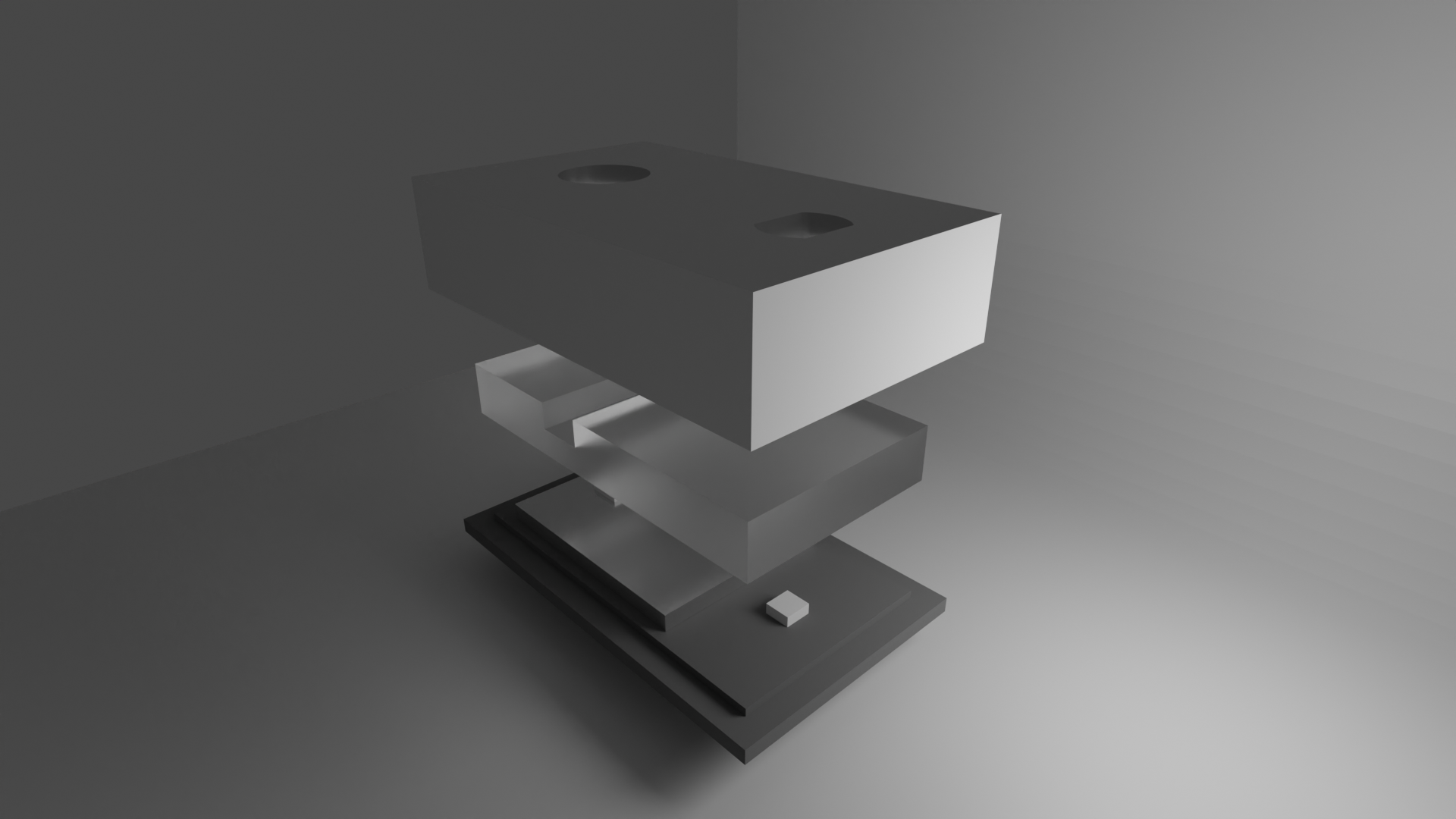

ICLED EVO 3838

A Revolutionary series of ICLED, redefining ambient lighting, featurin...

Interior Lighting

Interior Lighting

TOP LED 3030 RGB

Elevate your ambiance with our mid-power RGB LED, seamlessly coupling ...

TOP LED 3528

Conventional PLCC2 product series covering various color selections an...

TOP LED 2214

Conventional PLCC2 product series, featuring a range of colors and ada...

TOP LED 1608

Conventional PLCC2 product series, ideal for exterior applications.

ICLED EVO 3838

A Revolutionary series of ICLED, redefining ambient lighting, featurin...

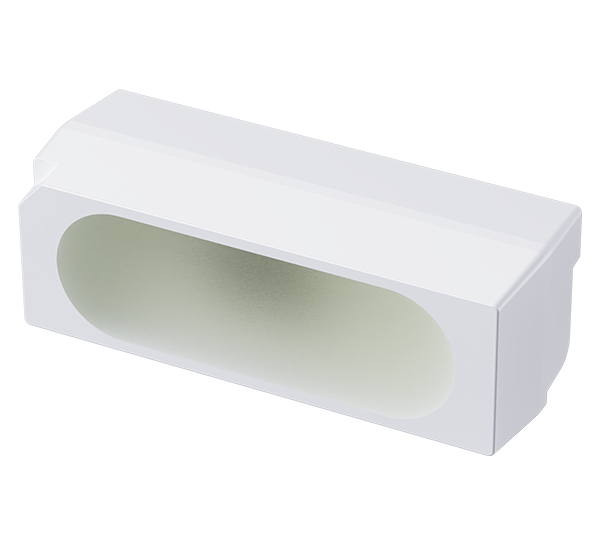

Exterior Lighting

Exterior Lighting

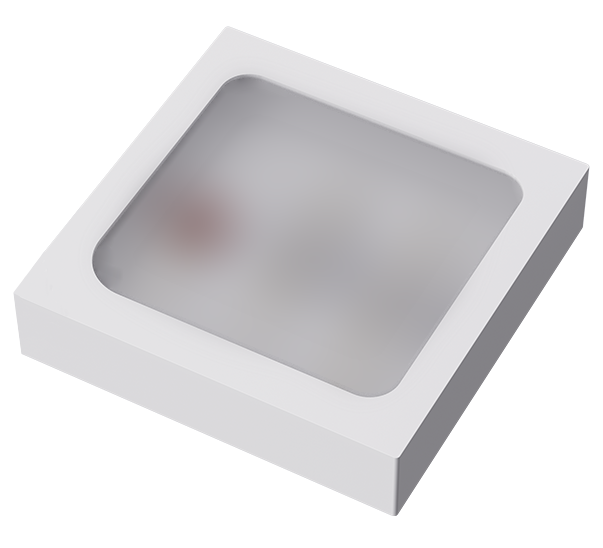

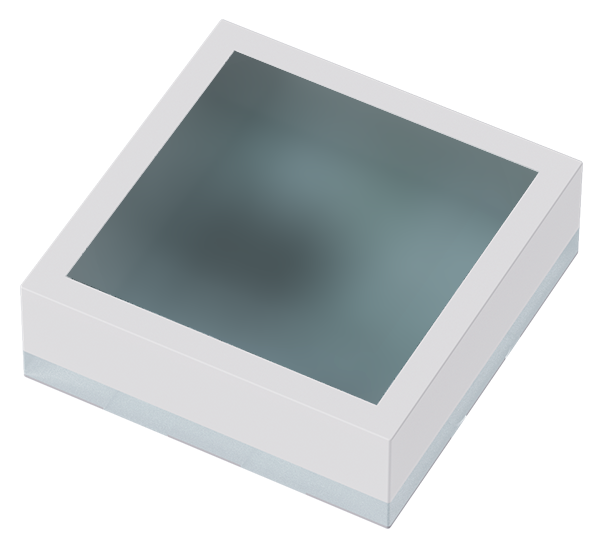

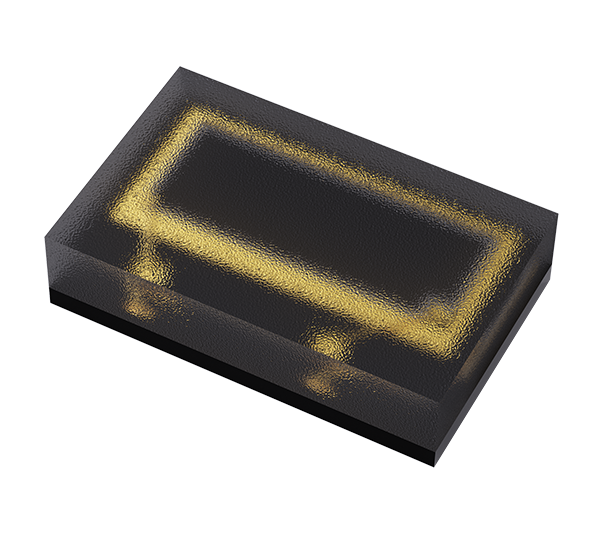

Power TOP LED 1519

Compact package with chip scale optical window for easily introducing ...

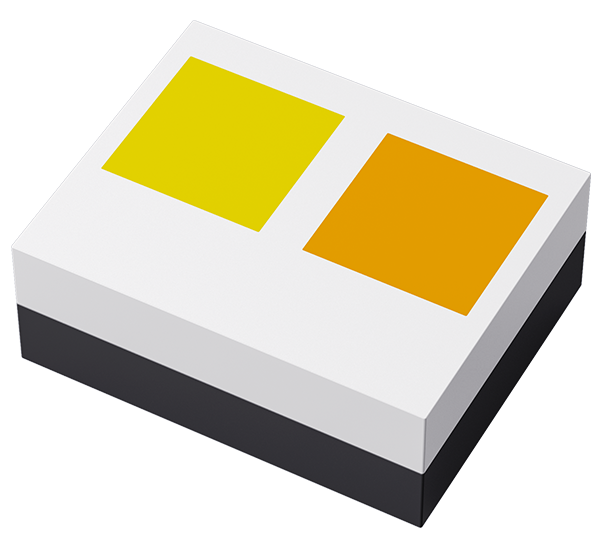

TOP LED 1519 Dual

Compact dual color package with chip scale optical window which is ben...

TOP LED 1519

Robust ceramic 0.5-1W LED, Ideal for design of daytime running and tur...

TOP LED 2720

Compact EMC products for rear lighting, offering a balanced selection ...

TOP LED 3433

PLCC chips in red and amber, offering high color purity for functional...

TOP LED 3433 RGB

0.2W PLCC6 RGB series, ideal for creating a variety of colors in ambie...

Wearables

IRR LED 2008

SMT Assembly Ready: Effortlessly integrate into your production. Inde...

IRRG LED 2020

Suitable for SMT assembly, emitters can be controlled separately

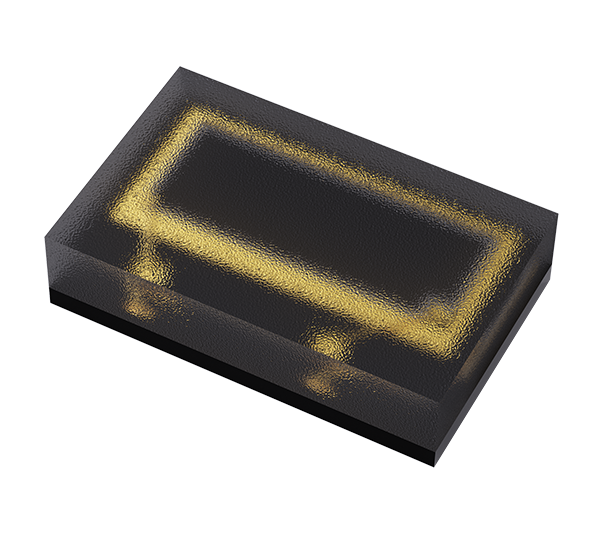

Photodiode 3220

Suitable for reflow soldering Especially suitable for applications fr...

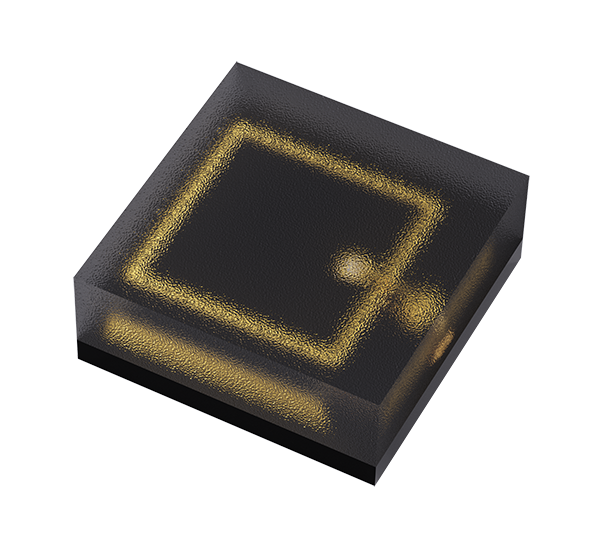

Photodiode 2020

Suitable for re-flow soldering Especially suitable for applications f...

OTS 2020

Gaming

Gaming

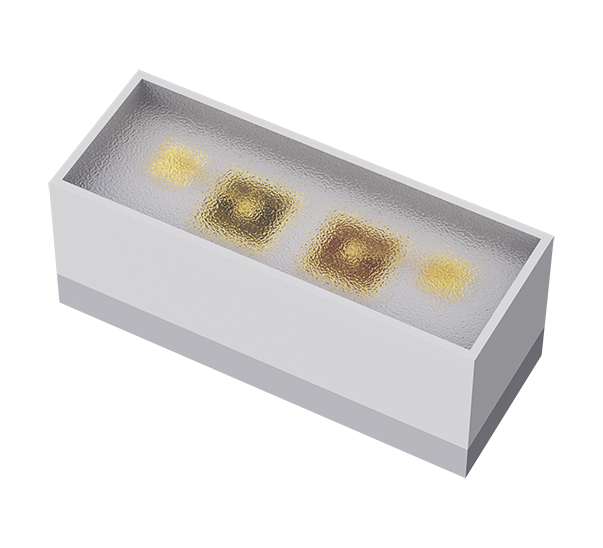

TOP ICLED 3535

Streamlining electrical circuit design for versatile color creation. W...

SIDE ICLED 4516

Side-view RGB ICLED, ideal for ambient light applications with an opti...

TOP ICLED 2020

Compact RGB ICLED for consumer, automotive, and display applications.

mini LED 0603

Enhance keyboard indicators with our high-brightness point emitter ser...

Mini ICLED 1212

Brightek provides automotive-grade RGB and smart LED solutions designe...

ICLED 5050

Experience brilliance with our high-brightness, large optical window I...

Security

Security

Power Dome LED 1616 80°

AEC Q102 Qualified series, engineered with low thermal resistance and ...

Power Dome LED 3838 40°/50°

Rated Class 3B for corrosion robustness, perfectly suited for Driver ...

Power Dome LED 3838 80°/90°

Perfectly tailored for Driver Monitor Systems and security application...

High Power IR LED 3838 (130° / 150°)

This automotive-grade high power IR LED is specifically designed for D...

Power Asymmetric LED 3838 45°x 25°

The Power Asymmetric LED 3838 45°x25° IR LED features a beam angle of ...

Power Asymmetric LED 3838 150°x90°

The Power Asymmetric LED 3838 150°x90° IR LED features a beam angle of...

-

Visible Lighting

Invisible Lighting

Videos & Brochures

LEDs

LEDs

SIDE LED 4516 RGB

Side-view RGB ICLED, ideal for ambient light applications with an opti...

TOP LED 3528

Conventional PLCC2 product series covering various color selections an...

TOP LED 1519

Robust ceramic 0.5-1W LED, Ideal for design of daytime running and tur...

TOP LED 1608

Conventional PLCC2 product series, ideal for exterior applications.

TOP LED 3433 RGB

0.2W PLCC6 RGB series, ideal for creating a variety of colors in ambie...

TOP LED 1519 Dual

Compact dual color package with chip scale optical window which is ben...

ICLEDs

ICLEDs

ICLED EVO 3838

A Revolutionary series of ICLED, redefining ambient lighting, featurin...

TOP ICLED 3535

Streamlining electrical circuit design for versatile color creation. W...

ICLED 5050

Experience brilliance with our high-brightness, large optical window I...

Mini ICLED 1212

Brightek provides automotive-grade RGB and smart LED solutions designe...

TOP ICLED 2020

Compact RGB ICLED for consumer, automotive, and display applications.

SIDE ICLED 4516

Side-view RGB ICLED, ideal for ambient light applications with an opti...

IR LEDs

IR LEDs

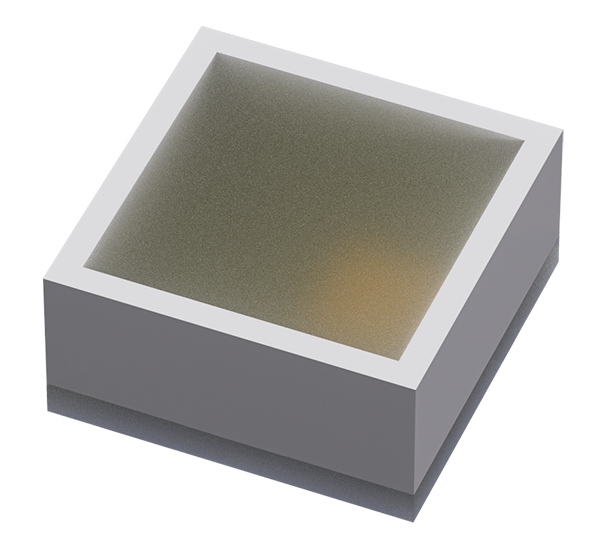

Power Dome LED 2720 80°

Compliant with the latest notebook camera specifications, the Power Do...

Power Asymmetric LED 1616 110° x 130°

This miniature automotive IR LED features an asymmetric beam angle of ...

Power Off-Axis LED 3838 135°x35°

The Power Off-Axis LED 3838 135°x35° IR LED features a beam angle of 1...

Power Flat LED 1616 130°

The Power Flat LED 1616 130° IR LED features a beam angle of 130° and ...

Power Asymmetric LED 3838 150°x90°

The Power Asymmetric LED 3838 150°x90° IR LED features a beam angle of...

Power Asymmetric LED 3838 45°x 25°

The Power Asymmetric LED 3838 45°x25° IR LED features a beam angle of ...

PPG

Photodiode 2020

Suitable for re-flow soldering Especially suitable for applications f...

Photodiode 3220

Suitable for reflow soldering Especially suitable for applications fr...

IRRG LED 2020

Suitable for SMT assembly, emitters can be controlled separately

IRR LED 2008

SMT Assembly Ready: Effortlessly integrate into your production. Inde...

-

Browse our technical videos and product brochures to explore our latest innovations.

See More

-

News

- Press Release Company Blog Events

-

Latest News

Dec 30 , 2025

Automotive LED Suppliers with Automotive-Grade Manufacturing Capabilities

Learn what automotive OEMs look for in automotive LED suppliers and how Brightek’s Nantong factory delivers automotive-grade cleanroom manufacturing, process control, and long-term...

Read More -

Latest News

Dec 22 , 2025

LIN-Lite Smart LED: Next-Gen Innovation for High-Efficiency Automotive Ambient Lighting

Reinventing Automotive Ambient LightingIn modern vehicle design, lighting plays a critical role — not only for aesthetics but also for driver comfort and safety. Traditional ambien...

Read More -

Upcoming Event

June, 2026

2026 DVN Detroit Lighting Workshop

- Sustainability

-

About Us

- About Us Our ManagementBrightek's JourneyContact UsCareer

-

We are Brightek.

An experienced solutions provider for Optoelectronic Semiconductor Components & Sensing Products. The Headquarters and R&D center are located in Taiwan, with sales offices and service market spreading worldwide. -

Our Management

Brightek’s management team brings over 20 years of experience in the optoelectronics market and technology, driving innovation, quality, and customer success. -

-

-

Explore Our Job Opportunities

We are a big family,

Check out your fit!

open to various possibilities.

-

Investor Relations

- Investor Relations Financial ReportsInvestment OpportunitiesPerformance HistoryManagement Team

-

We Are The Future You Can Trust

Listed in Taiwan Stock Market

Stock Number: 5244 -

-

-

-

Brightek

Brightek